Our job is to recreate, even to the touch, the sensation you get from the car you love or own.

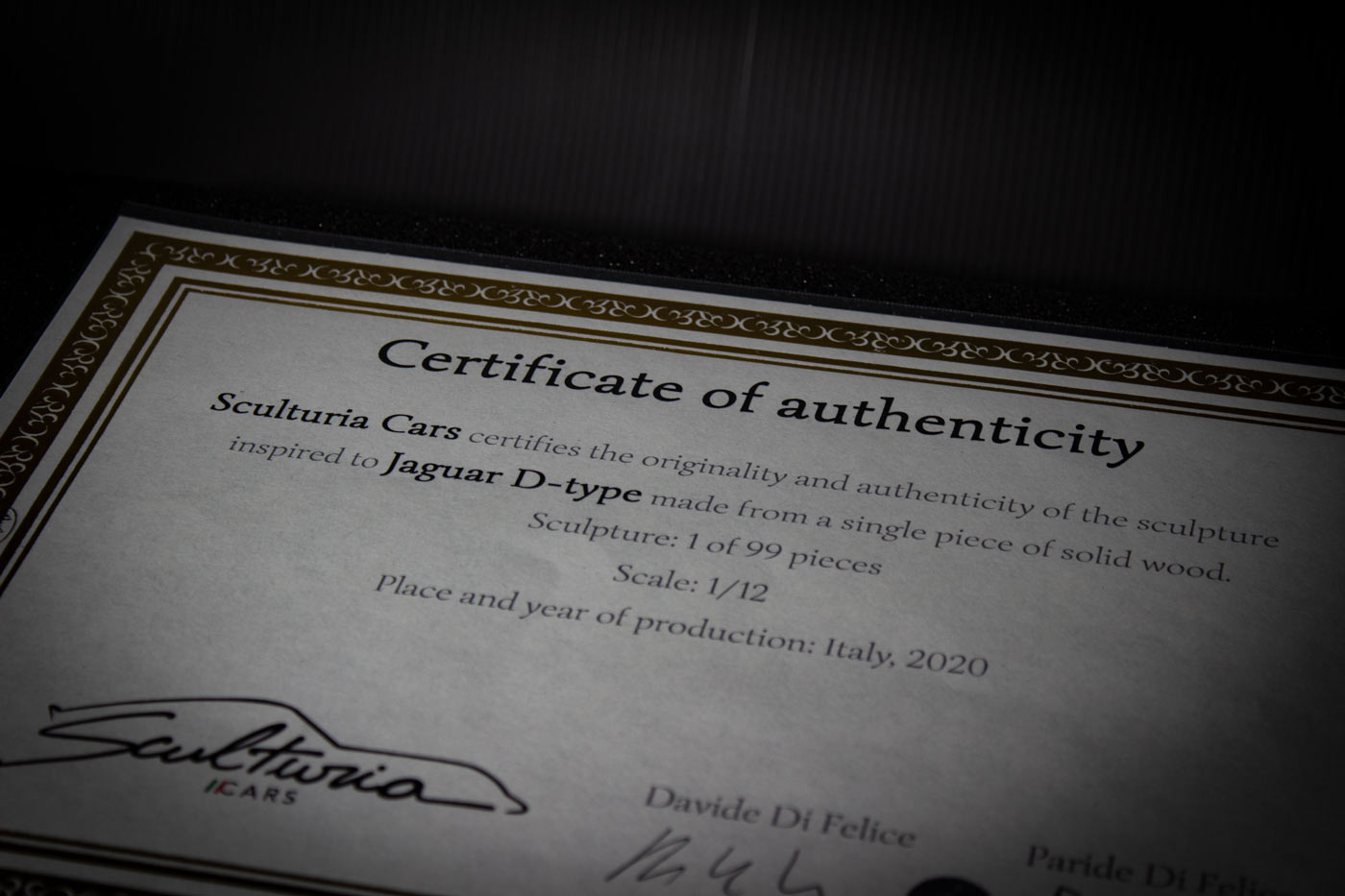

The final sculpture obtained is always unique. How is it accomplished?

To achieve this result, we use all the elements that make the artistic sculpture still great today through study, improvement of technique, to aspire for perfection; vision and patience (wait time). However, there is always a beginning, which for us takes the name of the wood “Okumè.”

Wood is a living material, always, and like us it has its fingerprints, the grain. It gives warmth and prestige to a piece of furniture, it is simply inimitable.

A work in solid wood can only be obtained by removing material, just like a sculpture, leaving the story of the tree intact in the heart of the object.

In Sculturia we have chosen Okumè, used in the nautical sector for its excellent properties of limiting distortions and lasting over time.

perfection, vision and waiting.

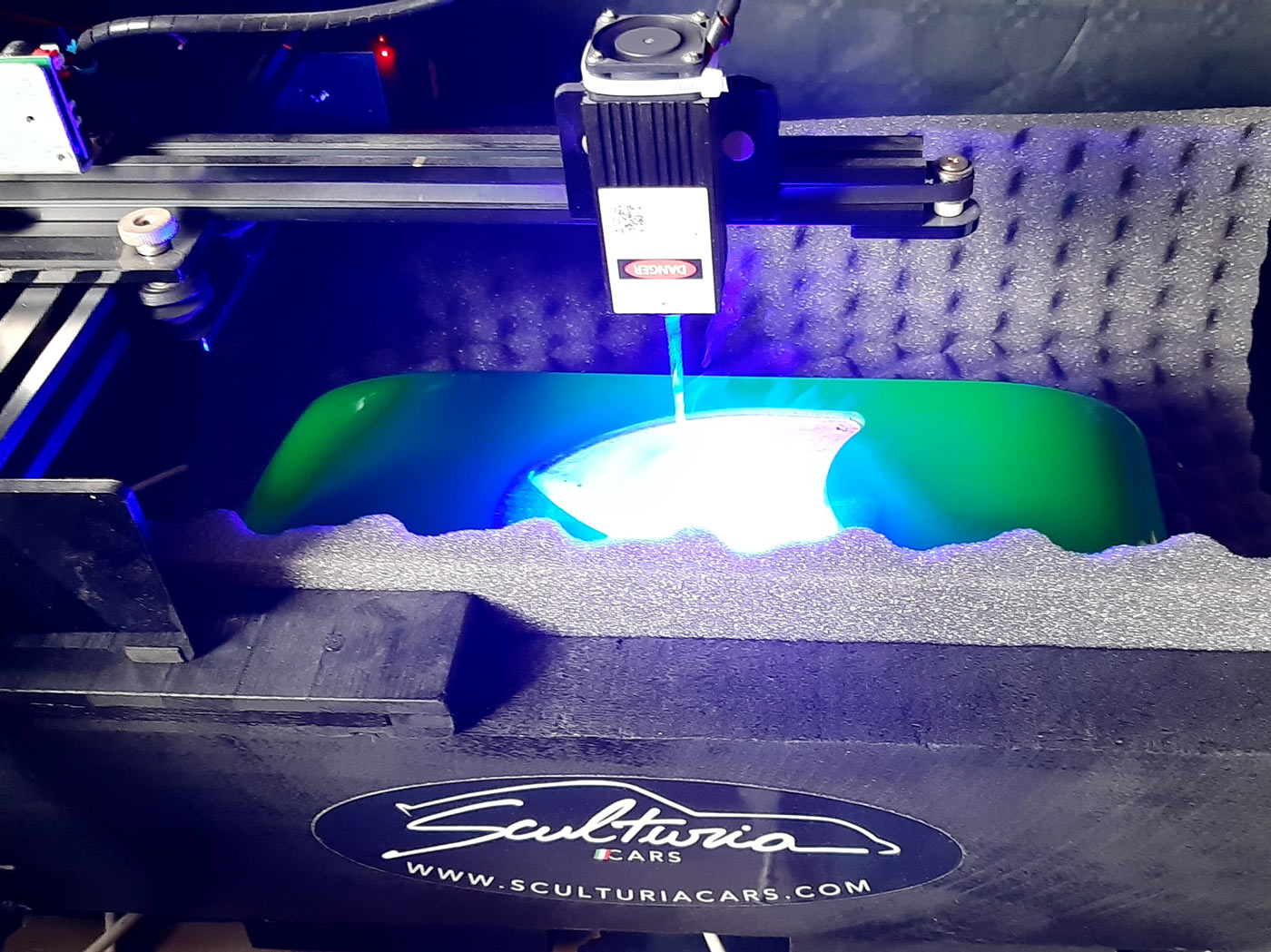

Our creations belong to the new generation of sculpture, where technology and manual work blend with the right balance to obtain an exclusive, prestigious and accessible product.

CELL PHONE

ADDRESS

SUBSCRIBE TO THE NEWSLETTER